A few months ago, I read an excellent posting by Lisa Irby about how to use Google’s Authorship feature. This feature was also mentioned in a blog posting on Google’s Webmaster blog as way to see your search impressions and clicks on articles for which you claimed authorship.

I had been curious about how some bloggers were getting their faces to appear next to their articles in Google’s search results so I was eager to give it a try. Upon following Lisa’s instructions, it appeared to do the job of claiming authorship for me, but my image was not appearing next to the results. The image I had on my Google Plus account at the time (and many other places for that matter) was of myself sitting in my LongEZ like the image shown to the right.  I began to ponder whether this was part of the problem since Google specifically requests a ‘recognizable’ headshot and I’m not very recognizable in that photo. I noticed that was a consistent feature of the faces that were appearing next to the articles, i.e., it was a headshot, not an icon or a image of their whole body. It was almost like Google was running the image through a facial recognition algorithm and if there wasn’t a recognizable face, then nothing would appear. So on my last visit to PA, I asked my brother-in-law, Jay Yozviak, Northeastern PA’s premier photographer, if he’d take a professional head shot for me. Whenever I tried to take a headshot of myself, it ended up looking like a mugshot, or at best, a namebadge ID photo. It seemed like no sooner did I upload my pro headshot to my Google Plus account than it started appearing next to my articles in a Google search.

I began to ponder whether this was part of the problem since Google specifically requests a ‘recognizable’ headshot and I’m not very recognizable in that photo. I noticed that was a consistent feature of the faces that were appearing next to the articles, i.e., it was a headshot, not an icon or a image of their whole body. It was almost like Google was running the image through a facial recognition algorithm and if there wasn’t a recognizable face, then nothing would appear. So on my last visit to PA, I asked my brother-in-law, Jay Yozviak, Northeastern PA’s premier photographer, if he’d take a professional head shot for me. Whenever I tried to take a headshot of myself, it ended up looking like a mugshot, or at best, a namebadge ID photo. It seemed like no sooner did I upload my pro headshot to my Google Plus account than it started appearing next to my articles in a Google search.

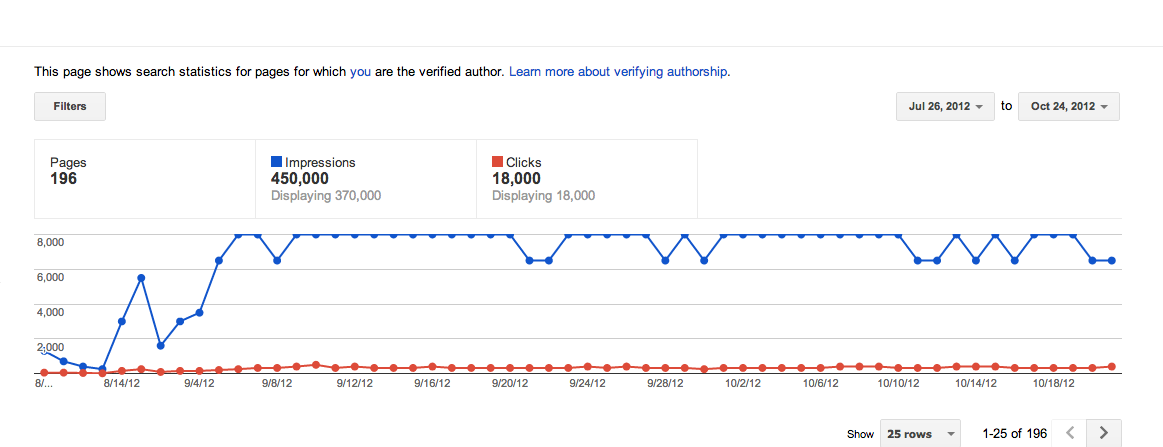

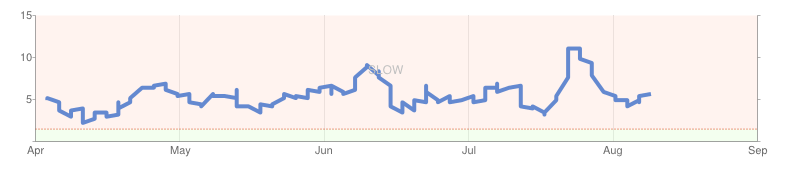

Later, I began to look at the number of impressions that were appearing in Google’s Webmaster Tools under Labs/Authorship stats and I noticed a graph that appeared to be bumping up some sort of ceiling of 8000 impressions per day. (You can click on the image below make it bigger.)

My website is hosted with GoDaddy on an IP address that also resolves to many other websites and it’s no speed demon. Sometimes it loads very fast, other times it can be downright slow. But I can’t complain about the price. For $7/month, they allow 150GB of storage and unlimited websites and bandwidth. On domaintools.com, I see that my IP shows over 4500 websites resolve to that server. Now, I expect that it’s not a single server, but a bank of servers that automatically do load balancing and all kinds of other cloud-like behavior, but I know that when Google was measuring my performance in the Webmaster’s tools, my site loaded slower than 80% of other sites and I can’t help wonder if Google intentionally will back off on the search impressions they show based on trying to keep the target host from getting overloaded if they detect a slow server.

The line across the bottom is the 20% percentile for all websites monitored. Therefore, my site with an average page load time of 5.8 seconds is slower than 80% of all sites.

Google’s all about speed, and if they find a slow server, they may just give it some kind of throttling in search impressions so as not to provide a bad customer experience. I’ve tried all the various tricks to make the site faster, caching, various pagespeed recommendations, db optimization, etc., but sometimes the site still takes a while to respond and load.

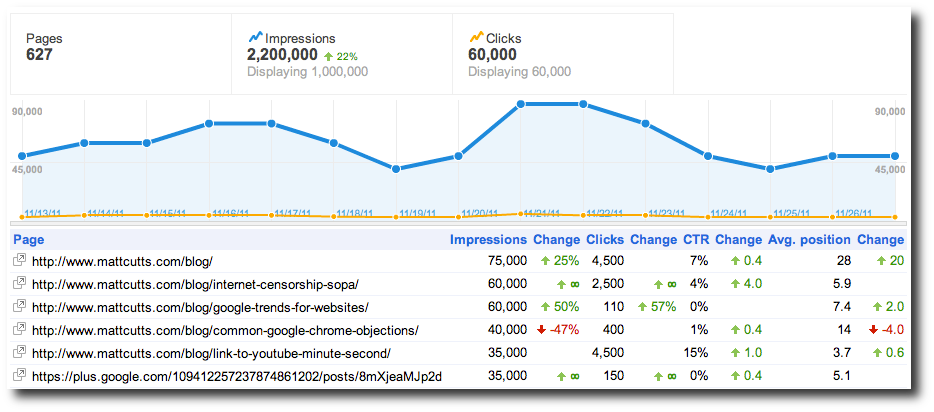

Going with a dedicated server costs a minimum of $100/month and I don’t know if there’s any guarantee that a single dedicated server will perform any better. And of course, that unnatural looking ceiling may be completely natural. There may be exactly that many searchers for the kind of results they’d find on my website every day for weeks at a time, but it just looks suspicious. In looking at the result for Matt Cutts’s blog which was used in an example in the posting mentioned above, he sees a much more varied number of impressions for his content over time, by a factor of two at least, without any apparent ceiling even though he’s getting 10x the traffic I am getting. But he’s also on a dedicated server. And.. He’s Matt Cutts :-).

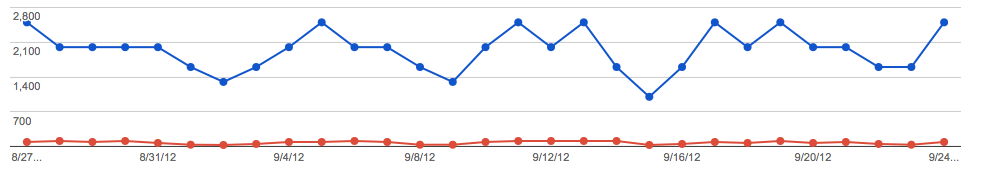

I can’t say for sure what’s going on here, but I know what clipping on an analog signal looks like and I’d say there is some kind of clipping going on with my number of impressions per day. I also understand that my graph is rounded off to the nearest 500 impressions, which can add quantization effects and make a line graph look unnatural as well. But I’ve also see a graph of someone who has fewer impressions per day than I do, and Google appears to resolve the impressions per day to fewer than 500 and I don’t see any clipping going on there. To me it looks very ‘natural’.

This graph was from someone on an seochat forum complaining about getting too few impressions per day, but I don’t know how he was able to deduce any pattern from the data, other than it never got above 2500.

Maybe Google is trying to do me, my hosting company, and my visitors all a favor, by limiting traffic to a reasonable volume. But if they are doing it, it would be nice to know about it for sure. And if you know how I can make a GoDaddy.com host (or shared/cloud server) that has thousands of other sites hosted on it run faster without having to pay 1400% more per month for a dedicated server, please leave a comment below.